Lắp đặt dao tiện

Turning tool set-up

Good quality in turning is mainly dependent on the tool system and how it is used together with the cutting material.

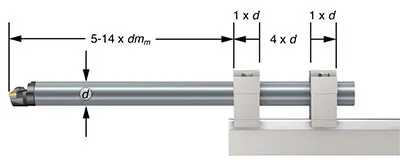

Overhang

For an optimal turning tool set-up, use a tool holder with as short overhang as possible to avoid vibration. We recommend to use a sub-spindle or tailstock for support if available.

When machining with long overhangs, it is especially important to mount the bar correctly to ensure enough clamping contact. Recommended clamping length is 4 × bar diameter (D). This will result in a stable tool set-up.

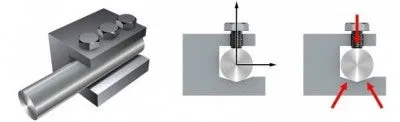

Cylindrical boring bars and adaptors can be clamped in split sleeves. Large boring bars and adaptors can be clamped using two split bearing caps.

Tool assembled with split sleeve

Tool fixed in two split bearing caps

Max tool overhang

| Bar type | Turning | Grooving | Threading |

| Steel boring bars | 4 x BD | 3 x BD | 3 x BD |

| Carbide boring bars | 6 x BD | 5 x BD | 5 x BD |

|

Steel damped boring bars  |

7 x BD 10 x BD |

5 x BD* | 5 x BD* |

|

Carbide reinforced damped boring bars  |

14 x BD | 7 x BD | 7 x BD |

| *570-4C bars |

For best performance of the boring bar, the contact, design, and dimensional tolerance between tool and tool holder are important factors. The best stability is obtained with a holder that completely encases the bar. V-type bar holder and cylindrical holder with screws are not recommended.

Holder that completely encases the bar

V-type bar holder

Cylindrical holder with screws

Bài viết khác

Tiện các loại vật liệu khác nhau

27/02/2025

Sử dụng nước làm mát trong gia công tiện

27/02/2025

Cách lựa chọn dao tiện

27/02/2025

Tăng tuổi thọ dao tiện

27/02/2025

Phương pháp đạt chất lượng sản phẩm tiện

27/02/2025